Frequently Asked Questions

Please check the owner's manual. It's packed with information and may answer many of your questions. Click here to view/download the owner's manual.

Please send us your questions. If they are questions that may help others, we will add them to the list!

- What are the differences between air deck and the aluminum deck? What is the best one for me?

- What type of outboard motor (long or short shaft) can be installed on Coastal inflatable boat?

- On the CBA 10.10 (10'10") what is the max weight of the motor? You say it can handle a 15 hp, but we all know a 15 hp 2-stroke is different then a 15 hp 4-stroke?

- How do I assemble my Aluminum deck?

- How do I find and repair an air leak?

- Why does my boat become soft after a few days?

- How does the boat air valve work?

- What documents do I receive with my boat?

- How to fix cavitation in a boat?

- If I want the boat shipped, what would it cost?

- Do you deliver?

Q: What are the differences between air deck and the aluminum decks? What is the best one for me?

A: This is a great question that needs to be covered in more details. We have an entire page that covers how to choose the right inflatable dinghy. . Click here to review it.

Q: What type of outboard motor (long or short shaft) can be installed on Coastal inflatable boat?

A: Short shaft 15" outboard motors are recommended to be installed on 15" transom of Coastal inflatable boats. Refer to the description of each model to see what the maximum motor capacity is recommended.

Q: On the CBA 10.10 (10'10") what is the max weight of the motor? You say it can handle a 15 hp, but we all know a 15 hp 2-stroke is different then a 15 hp 4-stroke?

A: The Max O/B Motor for each Coastal boat is listed in the technical specifications. What is meant by the Max O/B is the HP needed to bring the boat on plane when the boat is loaded to its maximum person/weight capacity. For example the CBA 10.10 is rated for up to a 15HP motor. A 9.8HP will move the boat nicely and will bring it to a plane with 2-3 people on board with no problems. But if you were to load the boat with 4 people plus gear bringing the total weight of the load to the maximum of 1210 lbs, then a 15HP would be needed to bring the boat on plane. For obvious reasons, the lighter the outboard motor the better. 2-stroke or 4-stroke engines may be installed on a boat transom. Keep in mind that any motor installed on a Coastal boat should be a short shaft motor. Long shaft motors may be used but it may create extra underwater drag.

Q: How do I assemble my Aluminum deck?

A: This is another great question that needs to be covered in more details. Excellent instructions are covered in the owner's manual. Click here to review it.

Q: How do I find and repair an air leak?

A: If you are losing air pressure check the boat over for air leaks. There will be normal air loss due to either the operation of the safe valve installed on the boat or due to change in the temperature. The best way to find air leaks is dish detergent mixed with water in a spray bottle. Start by checking the valves first. Spray around the valve on a suspected air chamber. If you see bubbles forming, check your valve fitting and base and be sure the valve insert is screwed on tight and push-pin is in correct position. If the leak is not in the valve, then spray the rest of the boat to find the leak. Spray the boat in small areas at a time until the entire boat is covered. Once the leak is found, cut out a patch large enough to overlap the damaged area by 1/2 inch on all sides. Center the patch over the damaged area, and with a pencil trace the outline of the patch. Apply masking tape around the perimeter of the outlined patch area to ensure a tight and clean glue line. Clean the patch area on the boat as well as the backside of the patch, its best to use M.E.K. (Methyl Ethel Ketone) patching solvent and cleaner. Use rubber gloves when handling solvent.

Apply three thin layers of adhesive with a short bristle brush, in a circular pattern on both the backside of the

patch and the patch area on the boat. Allow each layer to dry for 5 minutes before applying the next layer.

After applying the third layer, wait 5 minutes and then apply the patch to the prepared area and press down

firmly. Using a smooth object (a back of a tablespoon works well), working from the center of the patch to the

outside, force out any air bubbles that may have been trapped under the patch. After the patching is

complete remove the masking tape, place a 5 pound weight onto the patch and allow 24 hours drying time

before pressurizing the repaired air chamber.

Important: It is recommended to do repairs in dry weather. Humidity will decrease glue bond. Do not glue in cold temperatures.

Q: Why does my boat become soft after a few days?

A: There are a few reasons why your boat could be slowly losing air. The #1 reason is the temperature. Changes in temperature effects the pressure. When the temperature is hot, air expands and the safe valve on the boat allows air to escape in order to protect your boat. If air is escaping rapidly from a valve when you inflate your product, then most likely you are not properly locking the air valve.

Please note, that since air chambers are separated by inner baffles, it is possible that air leak in one chamber will cause other chamber to become soft too.

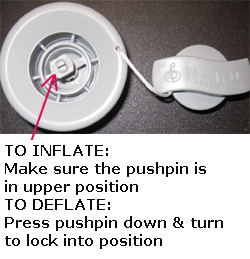

Q: How does the boat air valve work?

A: The valve has a special push-pin inside. Do not use any type of tool to adjust the position. Use your fingers! This push-pin has two positions, both up and down. When it is pressed in the down position, air will escape. If you turn the push-pin in any direction it will pop up. This will lock air inside and prevent it from escaping through the valve. Before inserting the air pump tube into the valve, please make sure that the push-pin is in the upper, popped up position. Once the pin is in the "popped up" position, insert the air pump tube into the valve and inflate the boat until it becomes hard. Once you remove the air pump, air will seal the valve and will no longer escape. If you would like to deflate the boat later on, press down on the push-pin and turn it in any direction until it stays in the pressed down position.

A: The valve has a special push-pin inside. Do not use any type of tool to adjust the position. Use your fingers! This push-pin has two positions, both up and down. When it is pressed in the down position, air will escape. If you turn the push-pin in any direction it will pop up. This will lock air inside and prevent it from escaping through the valve. Before inserting the air pump tube into the valve, please make sure that the push-pin is in the upper, popped up position. Once the pin is in the "popped up" position, insert the air pump tube into the valve and inflate the boat until it becomes hard. Once you remove the air pump, air will seal the valve and will no longer escape. If you would like to deflate the boat later on, press down on the push-pin and turn it in any direction until it stays in the pressed down position.

Q: What documents do I receive with my boat? Is that I will need to register my boat?

A:

You will need a Manufacturer's Statement of Origin (MSO) and Bill Of Sale. In most cases, that is all you will need to register your boat. Please call your State Registry Office first to see what documents you need and if any other documents are neede3d, contact us immediately.

Q: How to fix cavitation in a boat?

A: The #1 reason that causes cavitation is the fact that the boat is not fully inflated. If the boat's chambers are not fully inflated, this will cause water disturbance under the boat tubes, and cavitations as a result. Make sure that the boat is fully inflated. Use the hand pump to bring the boat to full pressure. Electric pumps will not inflate the boat to 100%. Use the hand pump fill the boat chambers until they are hard to the touch. Inflate the tubes until the hand pump becomes somewhat difficult to push down. When you push down on each tube there should not be much "give".

Q: If I want the boat shipped, what would it cost?

A: We ship our boats all over the 48 States. Shipping cost depends on your location. We normally use FedEx ground to ship our boats. In New England, the cost is normally under $150 with next day delivery. Normal delivery time for anywhere in the States is 3-5 business days. With the larger size boats, 12' and above, shipping costs increase due to the fact that the boat comes in 2 boxes, one for the boat and one for the deck. Shipping cost for those sizes are higher.

Q: Do you deliver?

A: If you live within a 100 mile radius of Portsmouth, NH we can deliver for a fee. Depending on the location, the fee could be anywhere from $95.00 to $250.00. .

Contact us for exact cost.